Plant Conveyors And Systems - An Overview

Table of ContentsIndicators on Plant Conveyors And Systems You Should Know5 Simple Techniques For Plant Conveyors And SystemsPlant Conveyors And Systems Fundamentals ExplainedPlant Conveyors And Systems Things To Know Before You BuyThe 10-Minute Rule for Plant Conveyors And Systems5 Easy Facts About Plant Conveyors And Systems Described

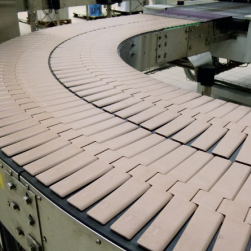

Carryback is typical in all belt systems as well as is just one of the significant problems that triggers belt malfunctions. Drive: The drive for the belt can be found in different settings in the communicating system. For many belt conveyors, the drive is situated at the discharge or head of the belt - Plant Conveyors and Systems.A/c electric motors are normally utilized to power the sheave that relocates the belt. Chapter Five Conveyor System Applications As automation as well as production have ended up being much more highly progressed, conveyors have actually quickly developed into an important part of material handling as well as motion as well as enhancing the rate of different production operations.

Conveyors transport the item right into the high temperature heaters for the sintering procedure. Packaging: A product packaging conveyor is created to assist with item packaging, such as putting finished items in containers, efficient labeling, or prep work of products for shipping. The function of a product packaging conveyor system is to move items from completion and also assembly for delivery.

The Main Principles Of Plant Conveyors And Systems

Press out conveyors are used to get rid of shaped items from the pressing line or on to various other operations. Airport terminal: Though airport terminals have people relocating conveyors, the main conveying system is for baggage handling, which quickens the procedure of getting baggage from the checkin counter to the aircraft and also off the plane to travel luggage pick-up.

Though mining conveyors vary in dimension and also size, most of them are on an incline and relocate several lots of material. They have to be equally packed to stay clear of spillage or voids. Depending on the layout, they run very swiftly up to 100 fpm. Mining Conveyor Automotive: The auto sector uses several selections of conveyors for material handling.

The one variable that makes them unique is the demand to satisfy governmental guidelines for hygiene and also cleanliness. Printing: Printing conveyors, for screen printing, use a conveyor dryer process for drying screen printed material. Though there are other techniques for drying screen prints, conveyor dryers are made use of for big volume production and be available in a number of ranges.

Not known Details About Plant Conveyors And Systems

Phase 6 Benefits of a Conveying System Conveyors have actually come to be a vital part of manufacturing, mining, manufacturing, as well as finishing procedures. They boost efficiency and also assistance decrease labor costs. The usage of conveyors has led to higher volume, boosted manufacturing, as well as avoidance of injuries. Regardless of the sector, conveyors have actually been shown to be an increase for production procedures.

Continuous Procedure: Products are constantly filled as well as unloaded for lengthy periods of time without disturbance or blockage. Automated Unloading: Conveyors can be designed to immediately dump materials without the requirement for hand-operated labor. Control of Motion: Sharing systems have speed controls to keep an eye on how quickly things relocate along the system, which eliminates the worry for handling issues or damage.

Some Of Plant Conveyors And Systems

The picture listed below is of a safety and security cable pick up conveyors. High Volume: Conveyors are a part of an automatic system efficient in moving hundreds or countless heaps of product per hr or in a day. Phase 7 Conveying System Malfunctions There are breakdowns that can take place in a sharing system that is continually being used.

Conveying System view it Malfunctions Mistracking Mistracking is also known as belt drift, where the belt drifts away. A misaligned belt can seriously harm the belt by irregular wear or damages products on the belt. The picture below is of a belt that has wandered to the. Confiscated Rollers Component of the mistracking problem may be associated with a seized roller, which can result in sharp sides that would certainly shut down the system.

Slippage Slippage on a belt conveyor can take place as a result of stress being too expensive or low, which can bring about extending as well as conveyor belt slippage. Blockage Conveyor systems are designed to run constantly without interruption or interruption. Any kind of obstruction can be damaging to the system and also result in major fixings.

Little Known Questions About Plant Conveyors And Systems.

The most typical is when product stays with the belt and also transcends the transfer factor and also diminishes. Carryback can be seen at the end of the picture below. Splilling When a belt conveyor is strained, or too packed, materials can fall off the sides. This can occur when workers are not educated correctly, or there is a trouble up the line.

Screw Conveyors Tiredness in a screw conveyor happens when there is construct up in the pipeline as the conveyor transforms. In that void, product collects and hardens.

How Plant Conveyors And Systems can Save You Time, Stress, and Money.

Repair or Replace Deciding to replace a component on a system has several cost factors, such as the downtime for the system, finding the right component, and working with a professional to do the substitute. This expenditure can be countered with routine maintenance as well as monitoring of the system. Motor The key component of a sharing system is blog here its electric motor (Plant Conveyors and Systems).

Bearing failure can be credited to lubrication troubles. This can be stayed clear of by having a routine maintenance cycle for bearing maintenance. The temperature degree of the motor should never surpass its suggested operating temperature. Pulley Bearings Wheel bearings are entirely filled up with lube to keep out water and also pollutants. Going Here In many cases, they never ever need fixing if they are regularly examined as well as maintained.